United States Department of Transportation (DOT, for short) as the functional department of American Government mainly develop and improve transportation and communication relevant regulations to meet the demand of environment and national defense, and Department of Transportation is a basic department of federal government as well, responsible for formulating and managing relevant policies, so as to protect and improve the safety, appropriate and effective of transportation system services.

The responsibilities of DOT are making traffic rules, and making provisions for all kinds of transportation ways and dangerous goods, issuing of certificates, etc. DOT devotes to traffic safety and economic growth. DOT has strict and specific management rules for traffic rules, traffic signals, lane markers, motor-vehicle administration, driver management, transport package, warning labels, etc. Carrying out the safety certificate is the common practice that the countries of the world do for ensuring the safety of consumers, evaluating and supervising the enterprises and their products that enter the local market, and is the effective means for enterprises obtaining international trade pass as well. It’s also the main reason of DOT certification becoming more and more popular.

DOT certification means the compulsive safety standard of traffic vehicles and safety components sold in American market by United States Department of Transportation. The manufacturers have to register basic information at relevant functional department and testify the products accord with relevant regulations.

The products that stick with DOT marks accord with the major requirements stipulated by DOT instructions and used for verifying the products have passed relevant tests or manufacturer’s test statement, to be the access pass for the products actually enter American market. Relevant regulations require the relevant products stick with DOT marks. The product will not be allowed enter market if without DOT mark; the product will be required to be recalled if the product doesn’t conform with safety requirements though it stick with DOT mark; the product will be punished to pay a heavy fine and have to stay out of the market if it breaks the DOT mark relevant rules continuously.

1、DOT certification range

U.S. laws require that vehicles (truck, car, trailer, autobus, motorcycle, school bus, etc.) and components (braking hose, braking fluid, lamp, reflecting device, tire, tire rim, glass, helmet, seat belt, seat, warning triangle, etc. ) sold and used in America have to pass the DOT certification.

DOT certification for motorcycle

As for as motorcycle, it needs to test and inspect the motorcycle whether meet minimum performance requirement of FMVSS from the aspects of braking system, control and display system and rear view mirror. In addition, the whole vehicle manufacturers should use braking hose, braking fluid, lamp and relevant parts, tire, tire rim, windshield, control and display device those components that have passed DOT certification.

DOT certification for lamp

FMVSS has requirements for all lamps on motor vehicles. Different lamps have different test items and requirements. But in generally the tests will detect whether the lamps meet the minimum requirements in different environments. The environment tests include: moist, corrosion, oscillation, dust, etc. Besides, testing the lamps color whether meet the requirements is needed.

DOT certification for tire

Tire as the main part of motor vehicle relate to safety is required by FMVSS as well. But the standard divides tire requirements into two types, the one type used on cars and the other type used on motor vehicles. No matter on the aspects of test, submitting the documents or production mark, the requirements for the two types tire are different.

certification for braking hose

FMVSS have set minimum performance requirements for hydraulic pressure, air pressure and vacuum braking hose. There are requirements for hose and the connector as well. Therefore, no matter the manufacturers of hose or hose assemblies both should conform to the corresponding requirements.

the manufacturer identification code of DOT certification

Only the three components manufacturers of braking hose tire and glass will receive the manufacturer identification codes distributed by Department of Transportation in the all whole vehicle and components which need certification.

The number is used for identifying the manufacturing plants of products; the all types products produced in the same plant could use the identification codes distributed.

2、Motorcycle DOT certification process

(1)Filling in the registration form;

(2)Estimating the insufficient section of DOT certification, difficulty level of products, tests that need to be done according to registration information, and then quote the price.;

(3)Signing a contract and pay the advance payment;

(4)The materials that clients need to provide: a. photocopy of company license b. engine code certificate, if have it c. all the components suppliers’ photocopy of company licenses d. components suppliers’ DOT test reports (if any) e. components suppliers’ DOT registration certificates (if any) f. other information of the components suppliers g. products instruction manual

(5)First telephone contact between the U.S. representative and DOT according to the materials provided by clients 5.5 make the test or registration asked by DOT up;

(6)Submit all information to DOT;

(7)The second telephone contact between the U.S. representative and DOT;

(8)Supplement the materials asked by DOT;

(9)Approved by DOT;

Technical information (need to be English information) that needed by DOT certification

(1)Product name、item list

(2)Main application

(3)Technical parameters

(4)Product structure diagram

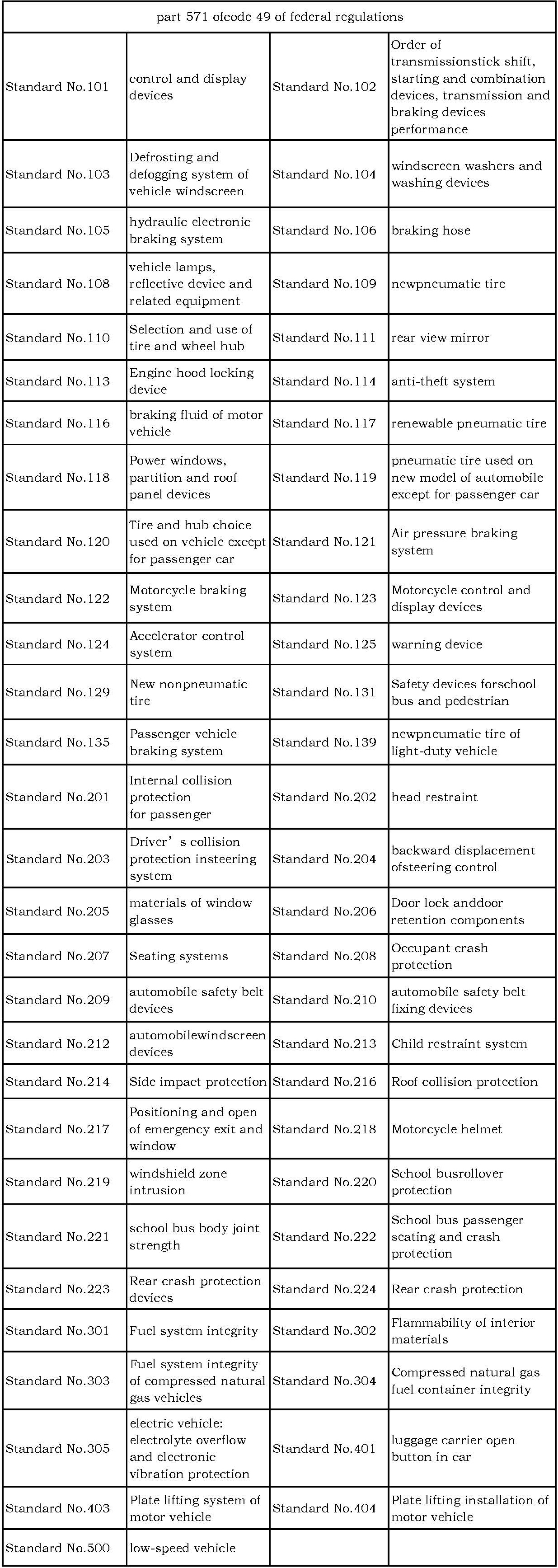

3、Federal Motor Vehicle Safety Standard (FMVSS) Introduction

4、DOT certification responsibilities of the manufacturer

The manufacturers of motor vehicles and components have the responsibility to confirm each motor vehicle and component conforms to the applicable minimum performance requirements of Federal Motor Vehicle Safety Standard (FMVSS).

Compared with other countries’ approval procedure such as Japan, it’s a self-certification procedure. Before or after the first vehicle or component sale, National Highway Traffic Safety Administration (NHTSA) do not approve label, affix label or trademark for issuing. Manufacturer could take any measure applicable to prove. The normal measures taken are testing according to FMVSS or conduct other research and analysis to confirm the conformance of products.

Not only have the manufacturer to take part in the original certification, but also keep monitoring in the production process of vehicle and component. To do this, building an effective quality control system is necessary, conducting the inspection and test periodically for the vehicles and components selected randomly from the assembly line to ensure its original performance runs through other all products.

Office of Vehicle Safety Compliance (OVSC) doesn’t specify the quality control procedure that the manufacturer should take. It’s decided by manufacturers. If the vehicles and components are considered reasonably in respect of safety, then the manufacturer can choose a sample monitor program to prove the changes of products will not break away the scope of completely conforming to standards. On the other hand, if the performance requirement is less than safety factor, then a more rigorous quality control procedure is going to be needed.